Deep Dive Into The Cost To Produce A Can Of Beer

Let’s kick it off with a question: how’s a new product get developed from an idea to a packaged beer on a retail shelf?

Typically new product concepts come from industry consumer insights.

Brewers routinely look at what’s trendy in different geographical regions.

Some brewers run the ideas through a more disciplined workflow. They ask questions like what unique capabilities and resources do we have, what are our constraints, is the new product idea aligned with our brand and target market.

Some brewers simply lean on their business acumen and gut feel. Guess and hope that there would be a large demand for their new products.

Once a new concept is greenlit then it moves into product development like tweaking recipes to land the desirable taste, texture, and alcohol percentage, working with the brand team and suppliers to design a compelling artwork for packaging, communicating sales strategies and marketing plan and securing buys from provincial liquor boards, and private liquor stores to ensure new product hits the market on the planned release date.

The idea-to-can process could be time-consuming…6 months is typical. It takes a community to make a beer as everyone contributes to ensure the new product is of high quality and consistently tastes great.

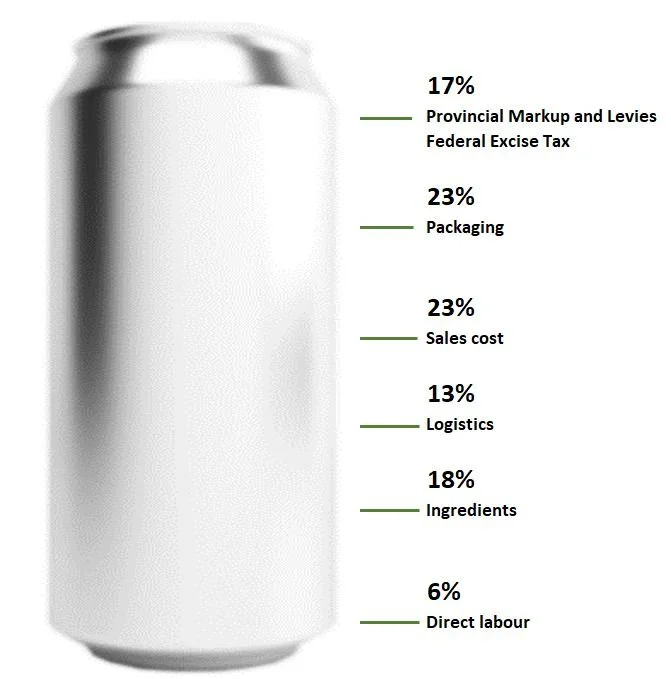

Here’s a graph that breaks out the final cost of a 473ml craft beer:

On average, it costs a craft brewer about $2 bucks to produce a can of beer.

To give you more context about what these costs actually mean, I will walk you through the direct inputs that go into one can of beer.

Taxes

Each provincial liquor board and the federal government levy tax called beer wholesale markup and federal excise duty. These tax rates are based on the production level. The more beer a brewer produces, the higher taxes a brewer pays.

For example, the BCLDB’s starting beer markup rate is 40 cents per liter. As soon as a brewery makes more than 15,000 hl annually, the markup rate starts to increase…to a maximum of 1.08 per liter for a brewery that produces more than 350,001 hl per year. [1]

Special note: hl is short for hectoliter. 1 hectoliter is 100 liters. It’s a volume measurement - a key benchmark used in the beverage industry.

Quiz time: How many 473ml cans do you need to package 15,000 hl? [2] You will find the answer at the end of the article.

Now back to taxes, the total provincial markup and federal excise duty a small-sized brewer can expect to pay 32 cents for each can of beer.

Packaging

Packaging cost is about 23% of the total cost. Most brewers buy in-bulk to get volume discounts and some brewers buy materials from overseas to keep the unit cost low. Packaging includes cans, lids, wraps, labels, mumms, cardboard trays that hold 6 packs of 4x473ml, and pallets for shipping.

A blank aluminum can with a lid costs 20 cents and more.

Because consumers want what’s new and the beer industry is moving away from using plastic holders, we are seeing more and more breweries put 4 packs in a fancy box. The end product looks amazing but this packaging innovation is surprisingly expensive (adds 25-50 cents to a can of beer).

Sales cost

Breweries need boots on the ground to merchandize their beer to retail stores, bars, and restaurants. Smaller craft breweries probably don’t have a full-time sales team so they hire a 3rd party sales agency to ensure that key accounts are buying their products, setting up displays in retail stores, and teaching people the proper way to serve and drink their beer.

Sales cost is about 40-60 cents per can.

Logistics

Shipping costs vary significantly by season. Trucking beer thousands of km costs a lot of money. Transporting during freezing winter is especially expensive (for example from Vancouver to the prairies). Breweries must use an insulated truck to protect their products because frozen beer is bad beer!

The average logistics cost adds over 20 cents to a can of beer.

Ingredients

The brewing industry is seeing raw material costs accelerating fast. Malt, a key ingredient that makes beer, soared 200% overnight due to low yield in recent harvest quantities. Nitric acid, a common cleaning chemical used in the food and beverage industry, cost increased above 30% due to global shortage. Some specialty beers include extra flavouring like fruity, nutty, coffee, and even cotton candy. Costs add up fast!

A typical 473ml can has over 30 cents worth of ingredients.

Direct labour

These are brewery employees who operate the brewing, blending, and packaging machinery.

The going rate for a non-union brewery is about $20 per hour. A brewer is expected to pay about 10 cents for labour per can.

$8.00 is the average direct cost for a pack of 4x473ml beer - from raw materials to packaged beer on a retail shelf.

Assuming a craft brewer wants to make a 30% margin. This means marking up 40 to 50 percent of direct cost before selling its beer to a wholesaler (BCLDB wholesale operations for example:).

It’s typical for a brewery to mark up their beer drastically by 50% to cover all the costs we’ve discussed so far. For brewery owners and operators, take a moment to read about how to Unleash Your Pricing Power.

A wholesaler might buy a 4 pack from a brewer for $11.60. Then mark it up by another 25-35 percent and sell it for $14.99 in a retail store.

In the end, consumers pay over $17 for a 4-pack of craft beer…once you add the 5% GST, 10% PST liquor tax, and the container deposit.

How much profit does a craft brewer get to keep?

About $3.60 for a 4-pack. That’s about a 31% margin.

Is this good, bad, or ugly?

It depends on a brewer’s cost structure because there are other operating expenses to be paid.

Overhead expenses

These expenses are typically fixed.

They don’t change regardless of the type of beer and the specific production process involved.

Fixed costs include leasing an ideal space for producing beer. Businesses also need insurance and security no matter the production volume.

It’s typical to exclude these expenses when calculating margin by SKU.

Final Thoughts:

Crafty breweries are in a constant state of product development and experimentation. And it takes time, money, and a lot of capital to transform a new product idea into reality. But as a crafty brewery, it’s really challenging to build a beverage business when all people want is what’s new!

The positive news is craft beer drinkers have gained a deeper appreciation for the innovation and passion that go into each can of beer. I hope that people have gained more insights into the craft brewery industry’s cost structure. So, paying $14-17 retail for a 4-pack starts to appear like a great deal. And supporting your local craft brewery industry is a responsible thing to do…socially and economically. How do you help a craft brewery become more sustainable? Invite your friends to grab a pint at your local breweries and pick up a few 4-packs on the way out.

By Sean Wang CPA, CMA - Founder | Margin Master | Mountain Biker

References:

[1] BCLDB Beer markup rates by production levels. The starting rate is 40 cents per liter for a brewer producing up to 15,000 hl. In Alberta (AGLC), the base beer markup rate is 10 cents per liter for small brewers making less than 14,000 hl annually.

[2] How many 473ml cans do you need to package 15,000 hl? That’s over 3.1 million cans.